Our Plant

1. Fabrication: Our fabrication plant has been designed & developed in such a way that

it can serve to multiple needs of the clients related to Hardware And Spare Investment Casting, Food Machine Parts Investment Casting, Industrial Valves Castings, Mining Equipment Investment Casting, etc. With the help of advanced machines and gadgets, we have

the capability to produce products ranging from 1.5 gms to 150 kgs.

Also, in order to avoid any downtime, we have access to various machines

like Arc Welding Machines for immediate repairing.

2. Team: Our workforce is consists of Several diligent and adroit personnel working under the guidance of sales and production head. Our team members are highly innovative and keep on coming with effective ideas that help us to attain client satisfaction.

3. Machines: We have access to all the necessary machines, some of them are mentioned below:

- Wax pattern machines

- Shot blasting

- Conveyor lines

- Shell De-Waxing machines

- Induction furnace

- Heat treatment furnace

- Sand blasting

- Spectrometer

- Shell firing furnace

- Cut off machine

- Plasma cutter

- Knock out machine

- Welding machine

- Bandsaw machine

- Lathe machine

- Straightening machine

- Grinding machine

- Belt polish machines

- Pneumatic tools

- Gas cutting machines

- RDSO approved lab

In addition, we have a power back up of DG set that help us to work without any interruption and accomplish the task before the deadline.

4. Process

- Firstly a die is made out of the desired component from metal negative.

- In the second step, the wax is injected into this die which helps us in bringing low melting point positive which is known as pattern.

- Then a shell is built via ceramic negative around wax positive.

- After the above step is over a wax positive is then melted which leaves a cavity in the shell.

- This negative is a monolithic ceramic mould which is in the exact dimensions and shape of the desired component.

- In the next step, metal is cast into the cavity.

- Afterward, the ceramic shell is broken to reveal the component of metal.

This is a mass production technique and high precision method of casting. Castings with tolerances as close as +/- 0.05mm are cast regularly. Furthermore, it is possible to divide the whole investment casting method into various sections, referred below:

- Designing die

- Die making

- Making of wax patterns

- Shell building

- Melting metal and pouring

- Shell knockout, grinding and fettling

- Heat treatment, in case required

- Finishing

- Machining, if required

- Polishing, if required

Our company, Vikas Hitech Castings is committed to maintain below-listed points:

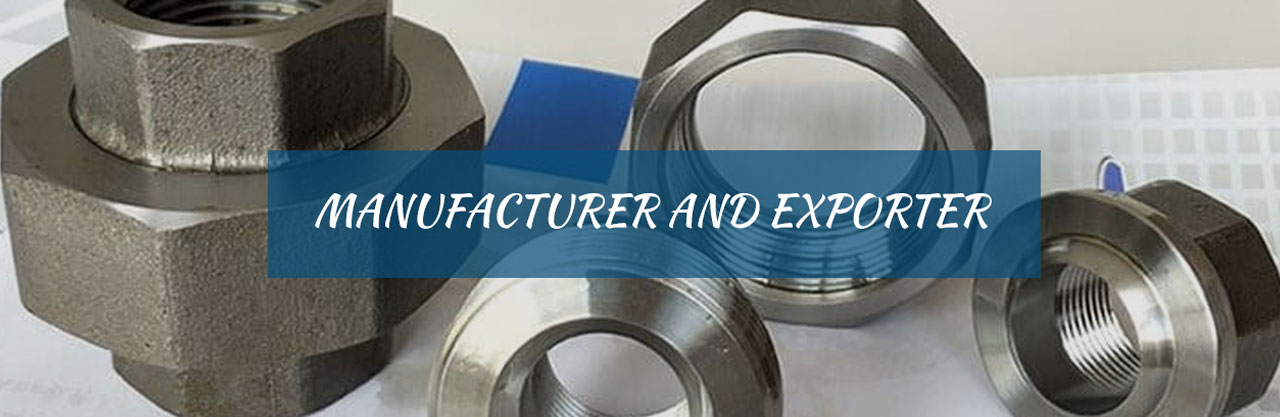

- Attain maximum client satisfaction through quality and timely delivery of all kinds of Cookware Investment Casting, Pipe Fitting Investment Casting, Fire Fighting Investment Casting, Flange And Socket Investment Casting, etc.

- Produce Mining Equipment Investment Casting, Textile Machinery Investment Casting, Construction Hardware Investment Casting, etc., in different sizes ranging from 1.5gms to 150kgs (per piece).

- We review quality management system that helps in business growth.

- It is on the basis of quality we have gained a huge prominence in the market and attained a huge customer base.

The mission of our enterprise is to maintain the reputation of a leading brand by fulfilling the expectations of clients in the best possible manner. Also, we envisioned to attain our set targets on time via teamwork by maintaining an excellent working atmosphere and become both customer-centric and employee-centric firm.

Resources

We are blessed with all the necessary resources in terms of machinery, technology and manpower which empower us to maintain a dominating place in the industry. Owing to our sufficient resources that we are able to keep our promise of utmost quality and timely delivery of Cookware Investment Casting, Pipe Fitting Investment Casting, Fire Fighting Investment Casting, etc. In the future too, we will keep on upgrading the resources that can help us to keep pace with the need of the hour.

Achievements

We have fulfilled the needs of multiple industries including Mini Steel Plants, Integrated Steel Plants, Rolling Mills, etc. We have earned the position of a prominent company in the market by providing quality products in Defense, Power Sector, Railways, etc. We have successfully set up a state of the Art Investment Casting Plant in Eastern India which is designed to cater to multiple needs of various industries. We can fabricate offerings from 25 gms to 50 kgs in one piece. Moreover, we have attained a huge customer base who are 100% satisfied with the quality of our goods and services.

|

VIKAS HITECH CASTINGS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |