Showroom

Our Stainless-Steel Casting permits for a quality finished result and fast turnaround, also offers a cluster material, sizes and arrangement choices. This might be the best decision for the customers throwing need.

Our Investment Casting infuses wax into a hole as aluminum has a reduced cost, is simpler to cut, and more affordable to keep up. Utilizing wax additionally is simpler on tooling, enabling it to keep up reliable parts for numerous applications.

Non-Ferrous Castings are very easy to use and safe to handle. Because they have favorable qualities like low density, a greater strength-to-density ratio, stronger conductivity, a non-magnetic feature, corrosion resistance, etc., non-ferrous metals are frequently utilized in structural applications. Large volumes of tiny to medium-sized goods are frequently produced with HDC.

This Fire Fighting Investment Casting utilizes a clay form that can deliver a much smoother finish, ordinarily averaging 125 RA surface completion as cast. This also minimizes work time and produce faster lead times since it extraordinarily diminishes the machining demanded to cast.

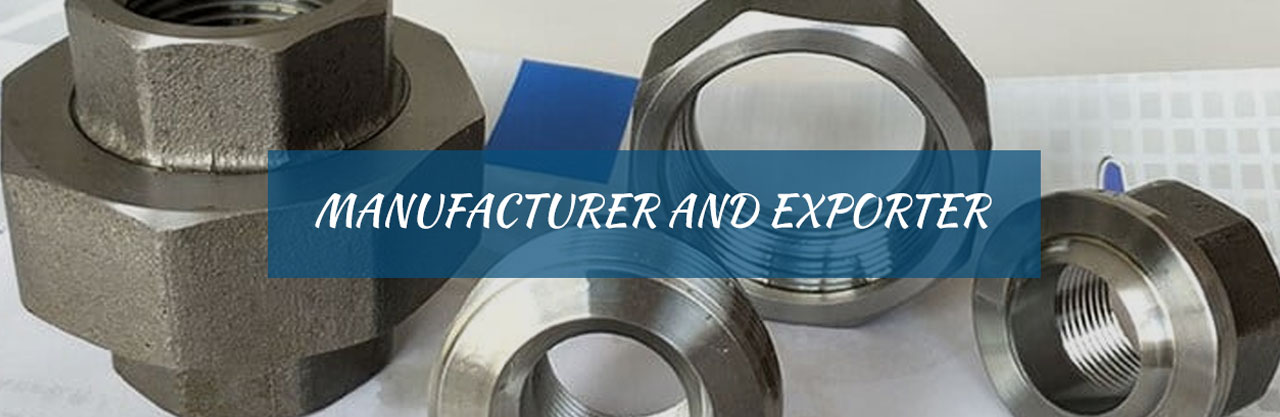

Our Flange and Socket Investment Casting hold more tightly resilience, which lessens the measure of machining required. The standard resistance is +/ - .005 for each inch. It requires affordable machines and is characteristically less risky, which makes expenses to stay low.

This Architectural Investment Casting permits for both small and huge casts. Multifaceted, scaled down parts that are 1/10 of an ounce or less can be thrown, and furthermore huge parts as much as 50 pounds can be thrown.

The provided Cookware Investment Casting requires affordable gear, and is naturally less hazardous, enabling expenses to remain lower. It likewise can hold tightly resistances while diminishing the size of machining run of the mill to forgings.

In our Mining Equipment Investment Casting, wax or reasonable polymer design is covered by dunking into the obstinate material slurry. When the headstrong material covering is solidified then this plunging procedure is rehashed several times to build the covering thickness and its quality.

When the last covering on our Textile Machinery Investment Casting is solidified, the wax is liquefied out and liquid metal has filled the pit made by the wax design. In addition, when the metal hardens inside the shape, casting is evacuated by breaking the mold.

Our Construction Hardware Investment Casting is referred to as a role as the missed wax casting. It is a procedure, which is equipped for making high precision and unpredictable castings contrasted with comparable assembling procedures, for example, sand casting.

Lost Wax Investment Casting is manufactured by making use of premium grade of raw materials and high technology. This casting is very easy to use and simple to operate. This casting requires very low maintenance and replacement costs. This casting is very effective and economical to use.

Fire Fighting Components save your life because you never know when a fire will start. They should only be used by certified fire brigade members. They are very effective and economical to use. Both at home and in the office, it's critical to have access to fire safety equipment.

Our Pipe Fitting Investment Casting can reduce down work time and offer one ceaseless part that has a steady and clean look to the end client. The decrease of work time lessens lead times and cost of castable applications.

Bonnet Bolt connection needs a gasket to seal the joint between the body and bonnet, unlike threaded and union bonnet valves. The majority of gate valves in industrial usage today employ the bolted-bonnet joint, which is the most common junction for gate valves.

"We mainly deal minimum order quantity approx 500 units."

|

VIKAS HITECH CASTINGS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese